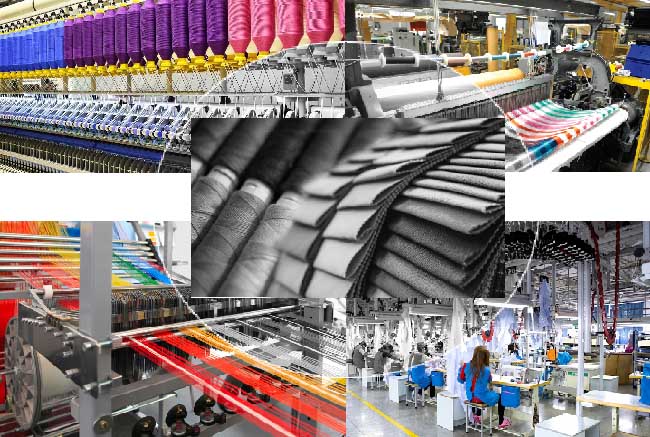

Screen printing and digital printing are two of the most popular methods of printing on a variety of materials. Both methods have their own advantages and disadvantages, and the best method for a particular project will depend on a number of factors, including the type of material being printed on, the quantity of prints being produced, and the level of detail required. Also checkout: Complete Guide About Textile Fabrication Process

Table of Contents

Screen Printing

In the process of screen printing, ink is applied to a substrate using a stencil. The stencil is created by creating a negative of the desired image on a piece of acetate or Mylar. The negative is then placed on a screen, which is a fine mesh stretched over a frame. An emulsion that is light-sensitive is subsequently applied to the screen. The emulsion is exposed to light through the negative, which hardens the emulsion in the areas where light hits. Then, a stencil is created by washing away the emulsion that was not exposed.

The ink is then applied to the screen using a squeegee. Onto the substrate, the ink is pressed via the stencil. The ink is then dried, and the process is repeated for each color in the image. Also checkout: How Textile Industry Works in Pakistan

Digital Printing

Digital printing is a process that uses a computer to create the image that is to be printed. The image is then sent to a printer, which uses a print head to apply ink to the substrate. The ink is applied in small dots, which are close enough together that they appear to blend together, creating the image. Also checkout: How Textile Industry Works in Pakistan

Differences Between Screen Printing and Digital Printing

There are a number of differences between screen printing and digital printing. Some of the key differences include:

Process:

Screen printing is a more manual process than digital printing. Screen printing requires the creation of a stencil, which can be time-consuming and labor-intensive.

Digital printing, on the other hand, is a more automated process.

Cost:

Screen printing is typically less expensive than digital printing for large quantities of prints. However, digital printing can be more cost-effective for small quantities of prints.

Resolution:

Screen printing can produce high-quality prints, but it is not as high-resolution as digital printing.

Digital printing can produce prints with very fine details.

Materials:

Screen printing can be used to print on a variety of materials, including paper, fabric, and metal.

Digital printing is typically used to print on paper and fabric.

Quantity:

Screen printing is best suited for large quantities of prints.

Digital printing is best suited for small quantities of prints.

Which Method is Right for You?

The best method for a particular project will depend on a number of factors, including the type of material being printed on, the quantity of prints being produced, and the level of detail required.

If you are printing on a large quantity of materials and do not need high-resolution prints, screen printing is a good option. If you are printing on a small quantity of materials and need high-resolution prints, digital printing is a good option.

Also checkout: Fashion Industry and its Sectors

Conclusion

Screen printing and digital printing are both viable options for printing on a variety of materials. The best method for a particular project will depend on a number of factors, including the type of material being printed on, the quantity of prints being produced, and the level of detail required. Screen printing and digital printing both process are very useful.

“This article was written by Bard, a large language model from Google AI.”