Table of Contents

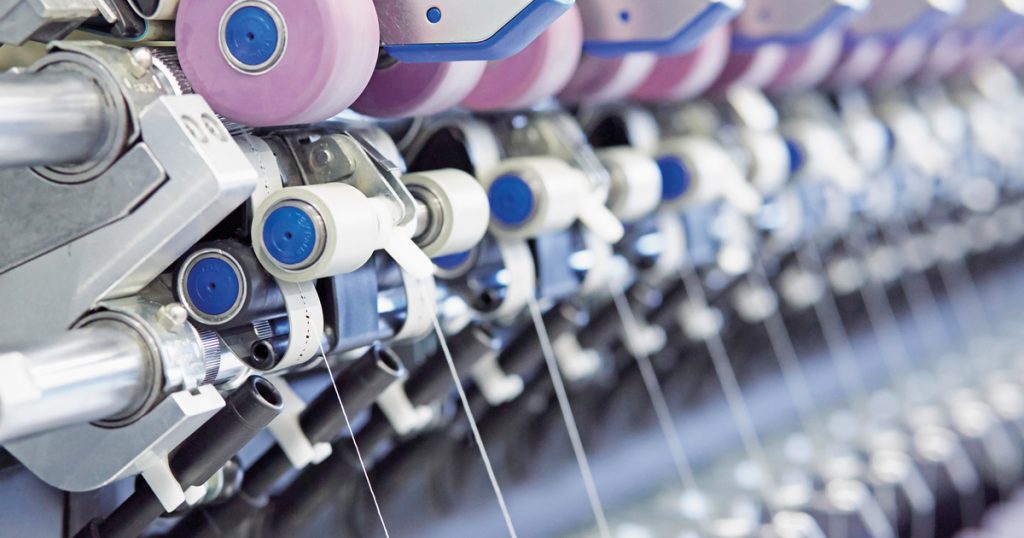

In this article we have discussed How Textile Industry Works in Pakistan. Pakistan is a major producer of textiles, and the textile industry is one of the largest and most important sectors of the Pakistani economy. The industry employs over 40 million people, and it contributes over 20% of the country’s GDP.

The textile industry in Pakistan is divided into two main segments: the spinning segment and the weaving segment. The spinning segment is responsible for converting raw cotton into yarn, while the weaving segment is responsible for converting yarn into fabric.

also checkout: How to Produce Fabric

Segments of How Textile Industry Works:

The spinning segment is the largest segment of the textile industry in Pakistan, and it employs over 25 million people. The spinning segment is dominated by a few large companies, but there are also a large number of small and medium-sized spinning mills. Spinning segment is plays a major role in how textile industry works in Pakistan.

The weaving segment is the second largest segment of the textile industry in Pakistan, and it employs over 15 million people. The weaving segment is also dominated by a few large companies, but there are also a large number of small and medium-sized weaving mills. Weaving segment is plays a major role in how textile industry works in Pakistan.

also checkout: Difference Between Screen Printing and Digital Printing

Numerous difficulties are being faced by Pakistan’s textile sector, including:

Competition from low-cost producers in other countries:

China is a major producer of textiles, and it is able to produce textiles at a lower cost than Pakistan. This has led to a decline in exports from the Pakistani textile industry.

Inefficient production methods:

The textile industry in Pakistan is characterized by inefficient production methods. This is due to a number of factors, including outdated machinery, poor quality control, and a lack of skilled workers.

Poor infrastructure:

The Pakistani government has not invested enough in infrastructure, such as roads, railways, and ports. This has made it difficult and expensive to transport goods to and from factories.

Despite these challenges, the textile industry in Pakistan is still a major contributor to the country’s economy. The industry has the potential to grow and become more competitive, but it will need to address the challenges it is facing.

How Textile Industry Works Can Be Improved

There are a number of things that can be done to improve the textile industry in Pakistan. These include:

Investing in new technology:

The textile industry in Pakistan needs to invest in new technology to improve efficiency and reduce costs. This includes investing in new machinery, adopting new production methods, and improving quality control.

Up skilling the workforce:

The textile industry in Pakistan needs to up skill its workforce to improve productivity and competitiveness. This includes providing training to workers on new technologies, production methods, and quality control.

Improving infrastructure:

The Pakistani government needs to invest in infrastructure, such as roads, railways, and ports, to make it easier and cheaper to transport goods to and from factories.

Promoting exports:

The Pakistani government needs to promote exports of textiles by providing incentives to exporters and reducing tariffs on imported inputs.

By taking these steps, the textile industry in Pakistan can become more competitive and contribute more to the country’s economy.

The textile industry is a major contributor to the Pakistani economy, and it has the potential to grow and become more competitive. However, the industry is facing a number of challenges, including competition from low-cost producers in other countries, inefficient production methods, and poor infrastructure. The Pakistani government and the private sector need to work together to address these challenges and improve the textile industry.

“This article was written by Bard, a large language model from Google AI.”